Climbing Skin Technology

Everything you need to know about how climbing skins work

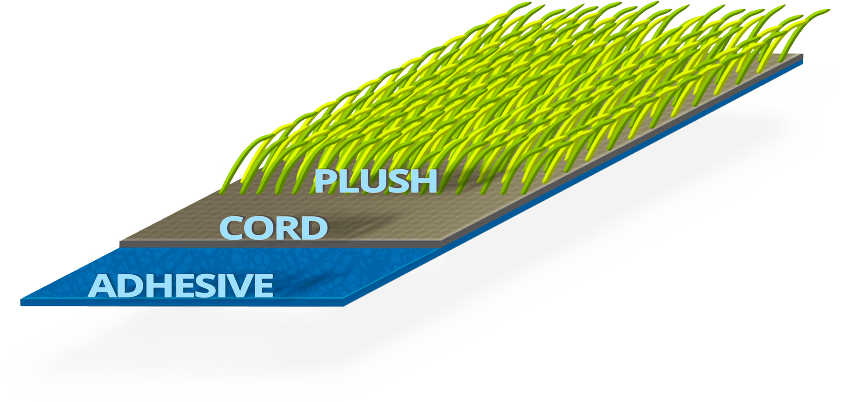

What's a Climbing Skin Made of?

Plush

This is composed of directionally oriented fibers that allow a skin to slide forward but not back.

CORD

This is the strong backing material to which the plush is affixed to and the glue is applied.

Adhesive

The temperature and water resistant glue that allows for temporary and repeated connection to a ski or splitboard while climbing, and removal for descending.

What sets BSMP Skins Apart

Our goals… reliability, durability, sustainability, and value.

We all know what a balancing act everything is in the backcountry. We are constantly having to adjust our plans based on snow quality, time, effort, difficulty and snowpack stability. At BSMP we simplify some of your equipment decisions by designing our gear to give you the best balance of performance and reliability in each category.

The world's most reliable skin glue

Our glue will never fail you in the backcountry. Period.

Durable Cord

Our backing material is a perfect combination of durability and weight designed specifically to latch onto our glue and never let go.

Plush Without Compromise

Both our mohair-mix and full-nylon plush are super-durable and have a low exit angle for unbelievable glide.

Strong Attachments

Our tip and tail connectors are super secure and utilize durable materials to stand up to the rigors of backcountry touring.

Performance Factors

Glide vs grip

This is the tradeoff between a skin’s speed over flat approaches and its ability to climb.

Adhesion

This is the ability of the skin to stick in cold and/or wet environments without leaving residue on the ski.

Glide vs Grip

A number of factors determine how well a skin climbs versus how well it glides. If you often tackle long approaches over flat terrain, glide may be a more critical factor in your choice of climbing skins and you’d likely prefer our mohair-mix plush. On the other hand, if you constantly find yourself on steep, icy skin tracks, grip may be more important and you may prefer our nylon skins.

Lets check out some factors that affect each:

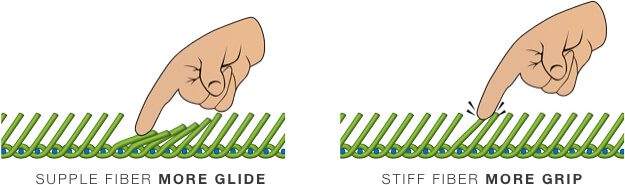

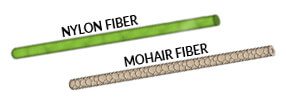

Fiber Stiffness

In general, a supple fiber provides superior glide while a stiffer fiber offers more grip. Our mohair-mix plush is more soft and supple which provides for superior glide. Our nylon plush is more stiff, which provides for superior grip.

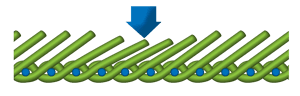

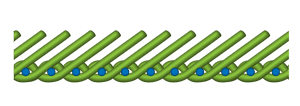

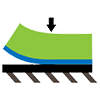

Fiber Exit Angle

Fibers that stand up straighter tend to have less glide than fibers that are oriented at an angle. We opt for a low angle fiber in order to maximize glide without compromising grip.

Fiber Material

Mohair is a natural fiber from goats. Nylon is produced through an industrial process. Mohair has more glide but slightly less grip. Nylon has more durability and grip but less glide.

BSMP Glide vs Grip Solution

Because skin plush is inherently grippy, we focus our engineering on solutions that maximize glide. The result is a product that offers plenty of grip while providing more glide than comparable skin plush.

OPTIMAL FIBER STIFFNESS

Our engineering allows for a perfect stiffness to provide optimal glide and grip.

Low Exit angle

Our construction methods weave a low exit angle into our plush layer to provide mohair like glide with nylon grip.

Quality, American-Made Materials

Our plush is composed of engineered mohair-nylon mix or full nylon fibers to allow you to choose your perfect balance of grip and glide.

Adhesion

Climbing skin glue must meet several difficult demands. If you’ve ever tried to use duct tape in wet or cold conditions, then you know what we mean. Climbing skin adhesive must work in temperature ranges between warm spring conditions all the way down to arctic temperatures. In addition, the glue must stick to wet or dry skis yet come off clean without leaving any residue. Lets take a look at some of the key factors of climbing skin adhesive and associated trade-offs.

How well does it stick?

Also Known as Peel Strength

How well a skin sticks to a ski is a measure of the adhesives bond. Cohesion refers to how well the adhesive sticks to itself rather than pulling off onto your ski. The factors we try and balance in adhesive design are:

PEEL STRENGTH TOO HIGH

Makes skins difficult to remove.

PEEL STRENGTH TOO LOW

Skins won’t stick to your ski or board.

COHESION TOO LOW

Leaves residue on ski.

COHESION CORRECT

Peels clean, no residue.

Temperature Range

targets: -40F — 70F

The adhesive on many skins does not work well in the cold, however, ours keep you moving no matter the temp.

BSMP Adhesion Solutions

At BSMP, our skin glue is one of our product’s defining qualities. While other adhesive is known for failing in wet or cold conditions, ours stays sticky, all the time, no matter what. When you purchase a pair of BSMP climbing skins, you can be sure to stay cruising whether you’re dipping into the sidecountry or 20 miles back on a major ski mountaineering mission.

OPTIMAL Peel Strength

Our adhesive gives you the optimal balance between stick and usability.

Wide Temperature Range

BSMP skins stick to temperatures as low as -40° F and above 70° F (if you find the need to tour in those temps).

Balanced Cohesion

Our skins stick well to your bases without leaving a residue, even in warmer temperatures.

NEW BSMP PRODUCTS HAVE ARRIVED

Ready to gear up? We got you.

Check out our ski skins, splitboard skins, and reglues.